With the advent of mass commercial beer brewing around the world, a host of hidden ingredients have made their way into the popular beers we drink today. But do you even know what’s in your beer? And what the difference is between beers and those with artificial ingredients?

As a beer lover, you might think all your favourite beers are brewed only with grains such as malted barley as a base, yeast for fermentation, hops for bitterness and aroma, and of course water. Not so, says master brewer, Helmut Grasreiner, Section Leader of Filtration at Namibia Breweries in Windhoek. “Nowadays, it is fairly common practice for breweries to add other ingredients to make the brewing process cheaper and faster. We don’t add any additives when we brew Windhoek Beer, because we still follow the Reinheitsgebot method of brewing, a German beer purity law which was decreed in 1516. This law prohibits us from brewing beer using anything but malted barley, hops, yeast and water. It also means we don’t take any mechanical or chemical shortcuts. It’s all for the sake of the purity of the beer,” says Grasreiner.

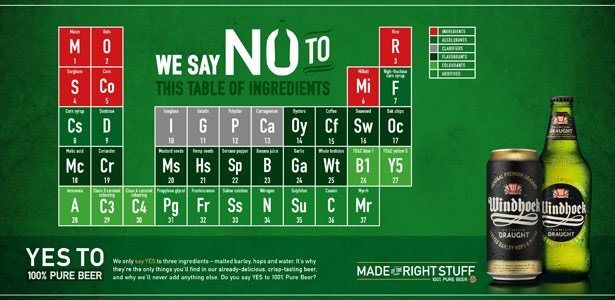

Common additives in commercially brewed beer

It is said that the use of strange additives in beer dates back centuries and that brewers in the 1800s even used pig bladder to speed up sedimentation and bile (gale) instead of hops to make beer bitter. Glucose has also been a common additive since the early 1900s. Today, hundreds of different additives, from herbs to chemicals, are added to beers around the world. Here are some common, but little-known ingredients that have started to make their way into commercially brewed beer:

• Isinglass: This extract from the swim bladders of fish is commonly used as a beer clarifier because it speeds up natural sedimentation (splitting of the clear liquid and impurities) of the beer. Unless a beer is labeled as vegetarian-friendly, drinkers may unknowingly be consuming animal by-products.

• Sugars: Corn starch, a glucose, is commonly used as an accelerant in the brewing process, as are other ingredients such as cane sugar. These sugars are used as alternatives to malted barley, they ferment at much higher temperatures, making the brewing process much cheaper and faster.

• Propylene glycol: This organic compound is used as an anti-freezing agent. The same chemical is used in smoke machines at rock concerts. It is generally regarded as safe to ingest in small quantities, and adds a sweetish taste, but can increase the body’s acidity if taken in large quantities.

• Sulphites: These naturally-occurring Sulphur compounds are often added to beer and wine as a preservative. Sulphites are generally safe to consume, but can cause allergy-like symptoms such as asthma and anaphylaxis in people with sulphite sensitivity.

• Rice: Rice, like other starches, is sometimes added to beer as an alternative to the more expensive malted barley. Rice in beer is more common in Asia than the rest of the world.

• Ascorbic acid: This synthetic form of Vitamin C is used to reduce O² (oxygen) in beer. Oxygen can make beer oxidise or ‘go off’. While safe to consume in small quantities, it can cause diarrhea if taken in large quantities.

• Flavourants: While some breweries use natural flavourants to add specific flavours to their beer, natural flavours can easily make the beer go milky, therefore many breweries prefer to use artificial flavourants.

What is so different about Reinheitsgebot Beer?

Two of the motivating factors behind the use of additives in beer are commercial pressures and concerns about oxygen in the beer. Windhoek Beer is however brewed according to the philosophy that prevention is better than cure, and that slow-brewing quality ingredients produces a better beer.

Many commercial breweries try to control the brewing process by letting machines do all the work. “Reinheitsgebot breweries are different. Luckily the strength of this tradition, coupled with the craft beer and home-brewing movement, is preserving the art of beer brewing,” says Grasreiner. At the Windhoek Beer brewery, for instance, oxygen is prevented from getting into the beer in the first place by filling the tanks with CO2 or water to push oxygen out. The brewery also employs highly-skilled brewers who train for a minimum of three years, of which seven months are spent at a 200 year-old brewing school in Ulm, Germany. As a result they have a hands-on approach to brewing the old-fashioned way, he says.

“This means the brewing process is more expensive,” says Grasreiner, “because only the finest malted barley from Europe, hops and filtered water are used. It also takes longer.” Windhoek Beer takes no less than 21 days to brew, whereas some commercial beers take only three to four days.

How do I distinguish between pure beer and beer with other additives?

Unfortunately, breweries are not obligated to label all of the permissible additives they put into their beers. This makes it hard for ordinary consumers to check all the ingredients in their beer.

However, if you look out for beers with the Reinheitsgebot emblem, you are guaranteed that these beers are slow-brewed with care, and contain only malted barley, hops and filtered water. The only other ingredient used in the brewing process, yeast, which is 100% natural, is removed from the beer before bottling.

“If beer is made well with quality ingredients and a passionate brewmaster, no shortcuts can be justified,” says independent beer expert, Lynnae Endersby, founder of Beer Lab in Cape Town.

Is it true that commercially brewed beer causes the worst hangovers?

Not necessarily. Many commercially-brewed beers are made from high-quality ingredients that won’t give you a hangover if consumed in moderation. It is however true that beers that are brewed very fast, at very high temperatures, with cheap ingredients, are more likely to contain higher alcohols (VDK’s) – impure types of alcohol – that cause hangovers.

One of the higher alcohols is diacetyl (VDK) which is formed during fermentation but gets broken down again (deacetyl rest) by the yeast after fermentation and that takes time and time is money and that is why some breweries don’t do it. So the diacetyl is still in the beer and if consumed can lead to headaches.

Note: Helmut Grasreiner started as an intern at Namibian Breweries in 1987 after completing the brewery’s rigorous three year training program.

– ADVERTORIAL –